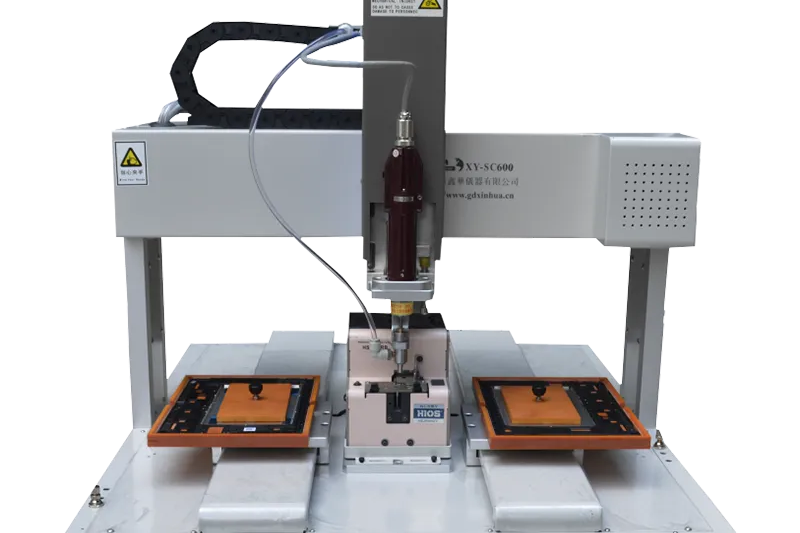

In today’s fast-paced manufacturing environment, efficiency and precision are paramount. The XINHUA Screw Locking Machine stands out as a vital solution for industries seeking to optimize their assembly line processes. By automating the screw fastening operation, this machine not only increases productivity but also ensures that each assembly meets rigorous quality standards.

One of the primary benefits of the Xinhua screw locking machine is its ability to provide consistent torque and fastening precision. Unlike manual screw fastening, which can be prone to human error, the Xinhua machine utilizes advanced technology to apply the correct amount of torque for each screw. This feature significantly reduces the risk of over-tightening or under-tightening screws, leading to improved product reliability and performance. In sectors such as electronics and automotive manufacturing, where precision is crucial, the Xinhua screw locking machine plays a pivotal role in maintaining high-quality standards.

Another significant advantage of this machine is its efficiency. The Xinhua screw locking machine can fasten screws at a much faster rate than manual methods. With its high-speed operation, it minimizes the time spent on each assembly, allowing manufacturers to increase their output without sacrificing quality. This is particularly beneficial in high-volume production environments where time is money. By integrating the Xinhua screw locking machine into their processes, businesses can enhance their operational efficiency and meet growing customer demands promptly.

Furthermore, the Xinhua screw locking machine is designed with user-friendliness in mind. Its intuitive interface allows operators to easily set up and adjust the machine for different screw types and sizes. This adaptability makes it suitable for various applications, from assembling consumer electronics to automotive components. Additionally, the machine can be integrated with existing production lines, providing manufacturers with a seamless transition to automated screw fastening.

In terms of durability, the Xinhua screw locking machine is built to last. Constructed with high-quality materials and components, it can withstand the rigors of continuous operation in demanding environments. Regular maintenance is straightforward, ensuring that the machine remains in optimal working condition, reducing downtime and repair costs. This durability, combined with its efficiency and precision, makes the Xinhua screw locking machine a worthwhile investment for businesses looking to improve their assembly processes.

The versatility of the Xinhua screw locking machine extends beyond just fastening screws. It can be equipped with various attachments and features that enable it to perform multiple tasks, such as screw feeding, tightening, and quality inspection. This multifunctionality allows manufacturers to streamline their operations further, as they can rely on a single machine to complete several assembly tasks. Consequently, businesses can reduce their equipment costs and minimize the space needed for multiple machines.

Moreover, the implementation of the Xinhua screw locking machine can lead to significant labor cost savings. By automating the screw fastening process, companies can reallocate their workforce to more value-added tasks, such as quality control and product development. This not only enhances employee satisfaction but also contributes to overall business growth by allowing teams to focus on innovation and improvement rather than repetitive tasks.