×

×

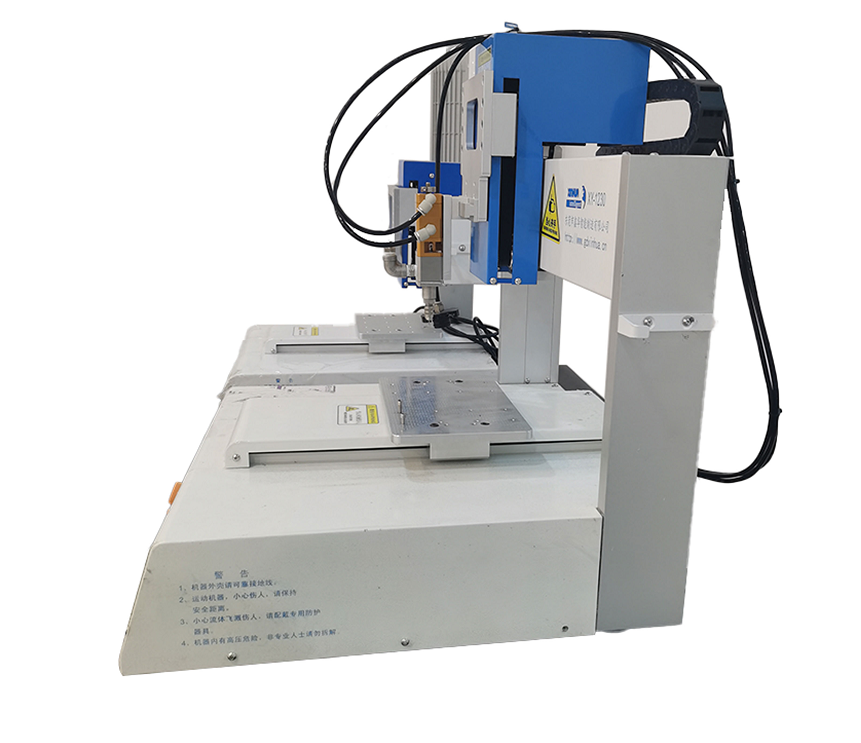

When using an Automatic Dispensing Machine, to ensure the normal operation of the equipment and the quality of the products, here are some important precautions to take:

Daily Cleaning and Maintenance: At the end of each workday, thoroughly clean the automatic dispensing machine, especially to remove any adhesive residue from the nozzle and the pipes to prevent the adhesive from solidifying and causing blockages. Also, inspect and clean the dispensing machine's calibration platform and the exterior of the machine to ensure there is no adhesive residue, keeping the equipment clean and tidy.

Transmission Mechanism and Component Maintenance: Regularly check whether the screws of the machine's transmission mechanism are tightened, including the X, Y, Z-axis rail transmission, amplitude adjustment mechanisms, etc., to ensure that the transmission mechanism is stable and not loose, avoiding any decrease in precision or malfunctions due to vibration. Regularly clean the screws and guide rails of the X, Y, Z amplitude adjustments and apply lubricating oil to prevent rust and wear.

Adhesive Management: When changing the type of adhesive, ensure that the pipes are clean. Close the feed valve, open the discharge valve, drain the remaining adhesive from the bucket, then pour in the cleaning solution to activate the machine, and flush the cleaning solution to ensure the pipes are clean.