×

×

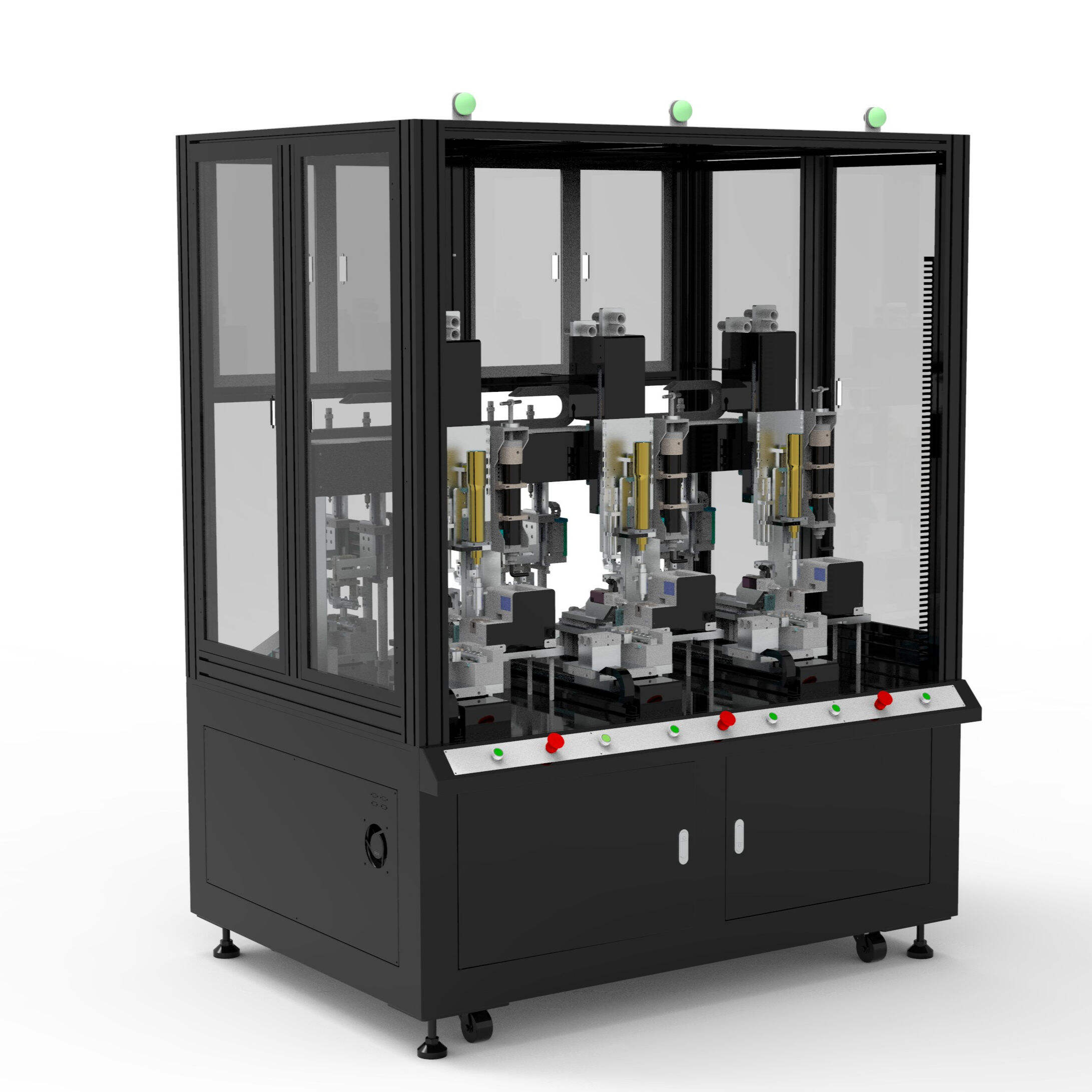

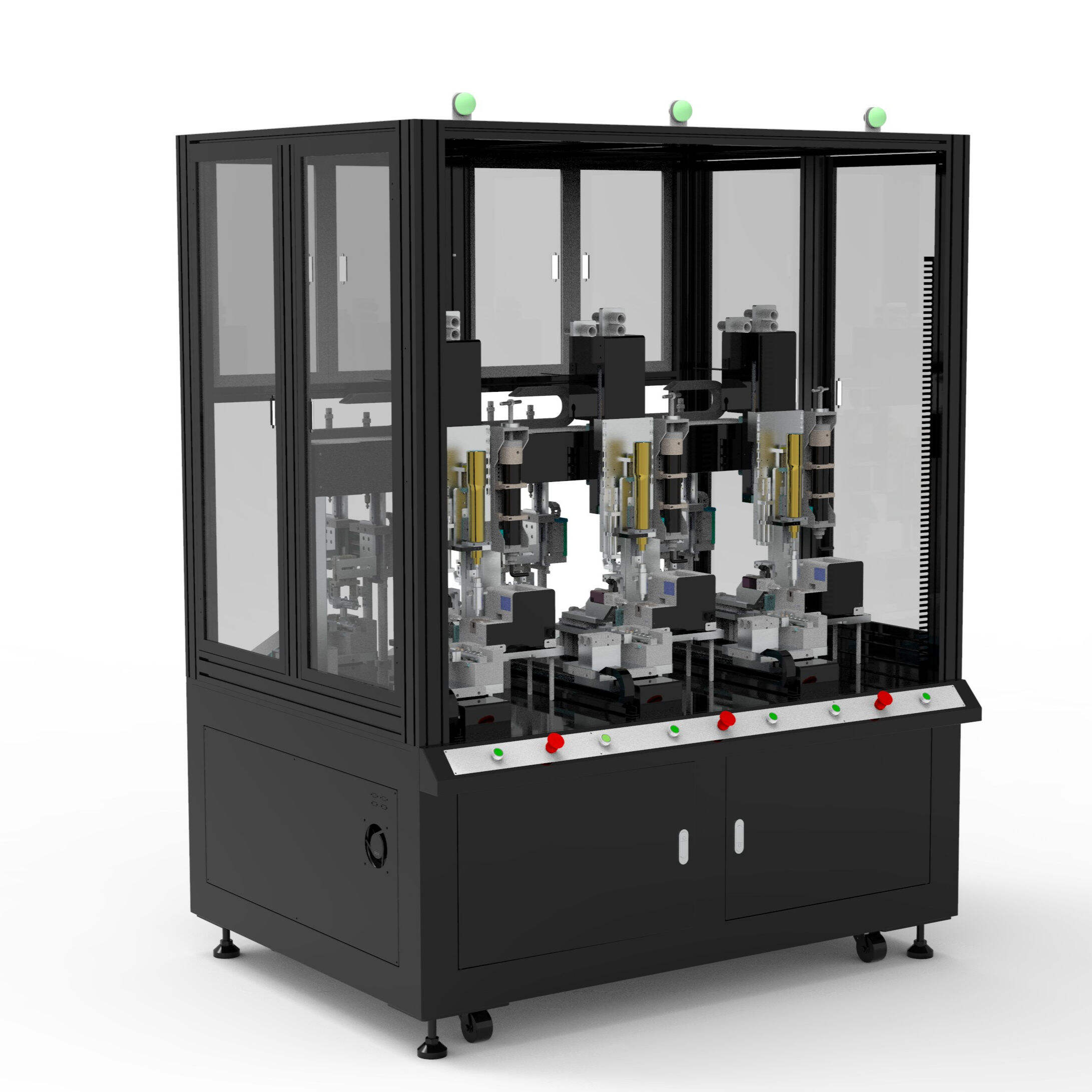

The automatic screw row unit is mainly responsible for screw screening, arrangement, material distribution, transportation and other processes. It is an important link instead of manual screw removal. Locking mechanism the locking mechanism performs the screw tightening action according to the program setting through the configured electric batch, air batch or servo motor, which completely replaces the manual operation

Many people will be curious about the automatic Screw Locking Machine and want to know how this product works. In fact, the automatic screw locking machine mainly includes automatic screw column unit, automatic screw conveying unit, automatic screw tightening unit and detection unit in the locking process. The screw automatic column unit is mainly used to arrange the bulk screws in order and output them individually. The column unit can be realized by the vibrating disk sorting mechanism or the rocker screw column mechanism; The automatic screw tightening unit comprises a rotating power part and a screw introduction part.

| Models | XY-AS373-T |

| Working area X*Y*Z*R(mm) | X1/X2:330*Y1/Y2:700*Z1/Z2:100mm |

| Moving speed (mm/s) | XY axis≤500mm/s,Z axis≤300mm/s |

| Drive mode | Stepping motor +straight guide/servo motor +ball screw(alternative) |

| Location accuracy | ±0.01-0.03mm |

| Control system | Moving controlling and teach pendant |

| Screw transmission method | Suction mode/blow mode (alternative) |

| Eectric screwdriver | 3pc(alternative) |

| Screw feeder | 3tower |

| Full-voltage | 220V 50HZ |

| Operating temperature | 5-40℃ |

| Operating humidity | 20-90% no condensation |

| Air pressure | 0-0.8MPa |

| Dimension W*D*H(mm) | 1235*1080*780 |

| Weight | around 420kg |