×

×

Semiconductor Packaging、 PCB Electronic parts fixing and protection、 New energy products dispensing 、 SMT industry dispensing, coating 、 L CD glass organic board encapsulation adhesion、 Mobile telephone board coating or key dispensing、 Speaker dispensing 、 Battery box dispensing sealing 、 Lighting products sealing 、 Auto parts coating、 Hardware parts coating then 、 cloth anti-skid coating、 Quantitative gas, liquid filling coating、 Chip bonding etc.

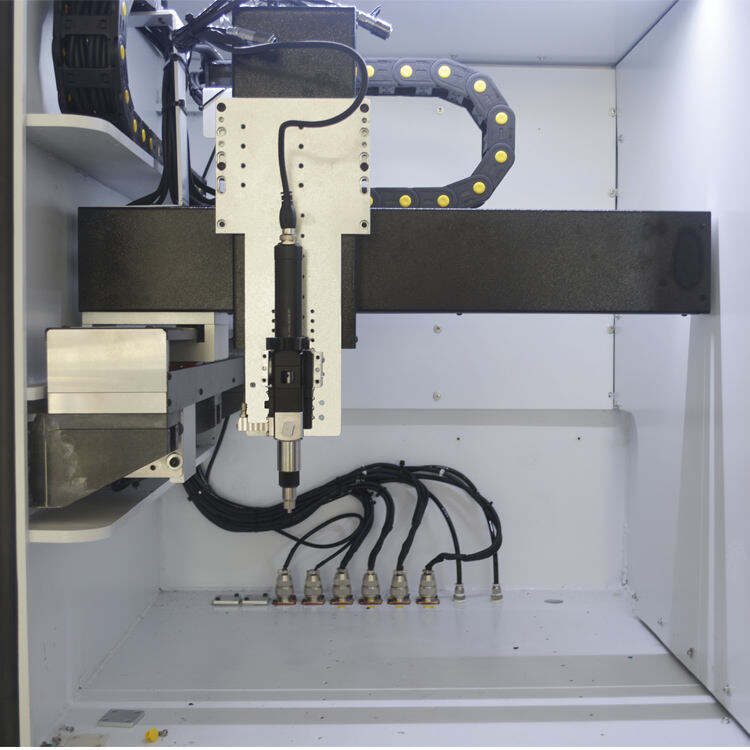

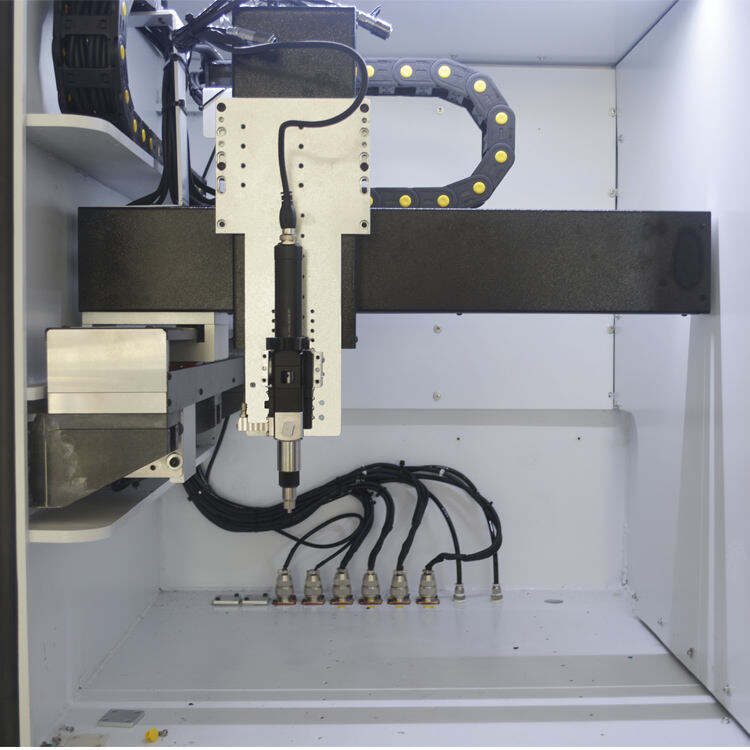

The product is placed in the vacuum box, and the double liquid is mixed according to a certain ratio, and then the glueis poured. The purpose is to greatly improve the glue quality. reduce the bubble formation, high degree of automation, shorten the process, improve production efficiency. Suitable for double liquid epoxy resin, double liquid polyurethane, double liquid silicone rubber and other double liquid fluid materials, suitable for the potting products with complex structure and high quality requirements.

| Models | XY-SR3301 automatic vacuum double liquid glue fling machine |

| Working area | X300*Y:300*Z:100mm |

| Maximum load | X/Y:20kg;Z:8KG |

| Moving speed | X/Y:≤500mm/s;Z:≤300mm/s |

| Operation mode | Single action, linkage, automatic |

| Driving mode | Servo motor +ball screw/stepping motor +linear guide rail |

| Proportioning accuracy | ±1%-3% |

| Ejection accuracy | ±3% |

| Motion accuracy | ±0.01mm-0.03mm |

| Mixing ratio | 1:1~100:1(Customizable) |

| Negative pressure value | -0.096MPa |

| Pressure barrel | 2 stainless steel vacuum storage barrels and 1 cleaning barrel (the volume can be customized according to customer requirements) |

| Mixed mode | Dynamic/static mixing |

| Operating system | PLC+PLC+touch screen |

| Input power | AC220V 50-60Hz |

| Operating humidity | 20-90% no condensation |

| Overall dimension | around W1000*L800*H750mm |

| Weight | around 500kg |