×

×

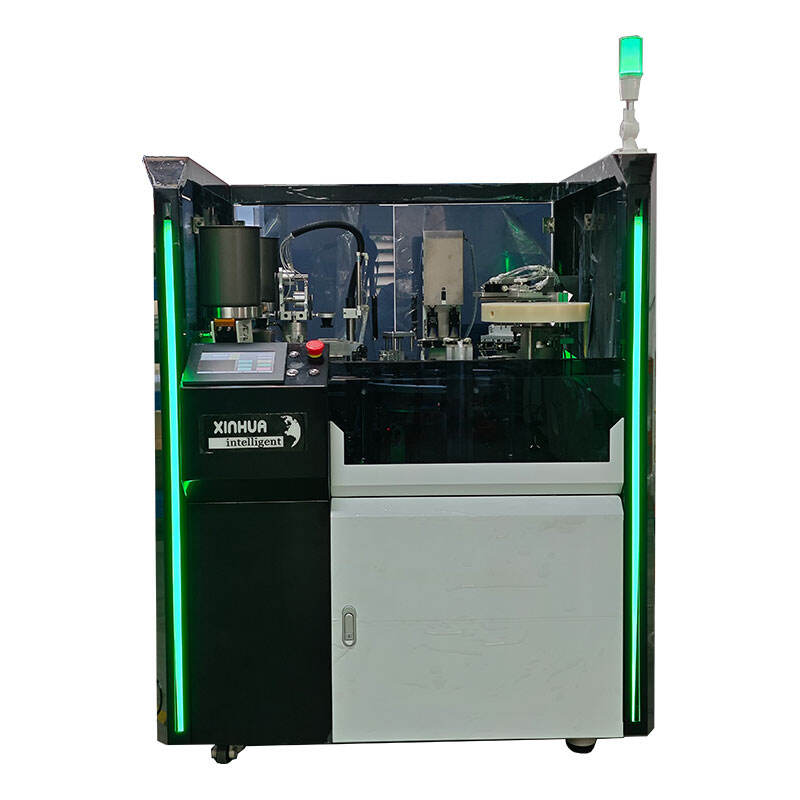

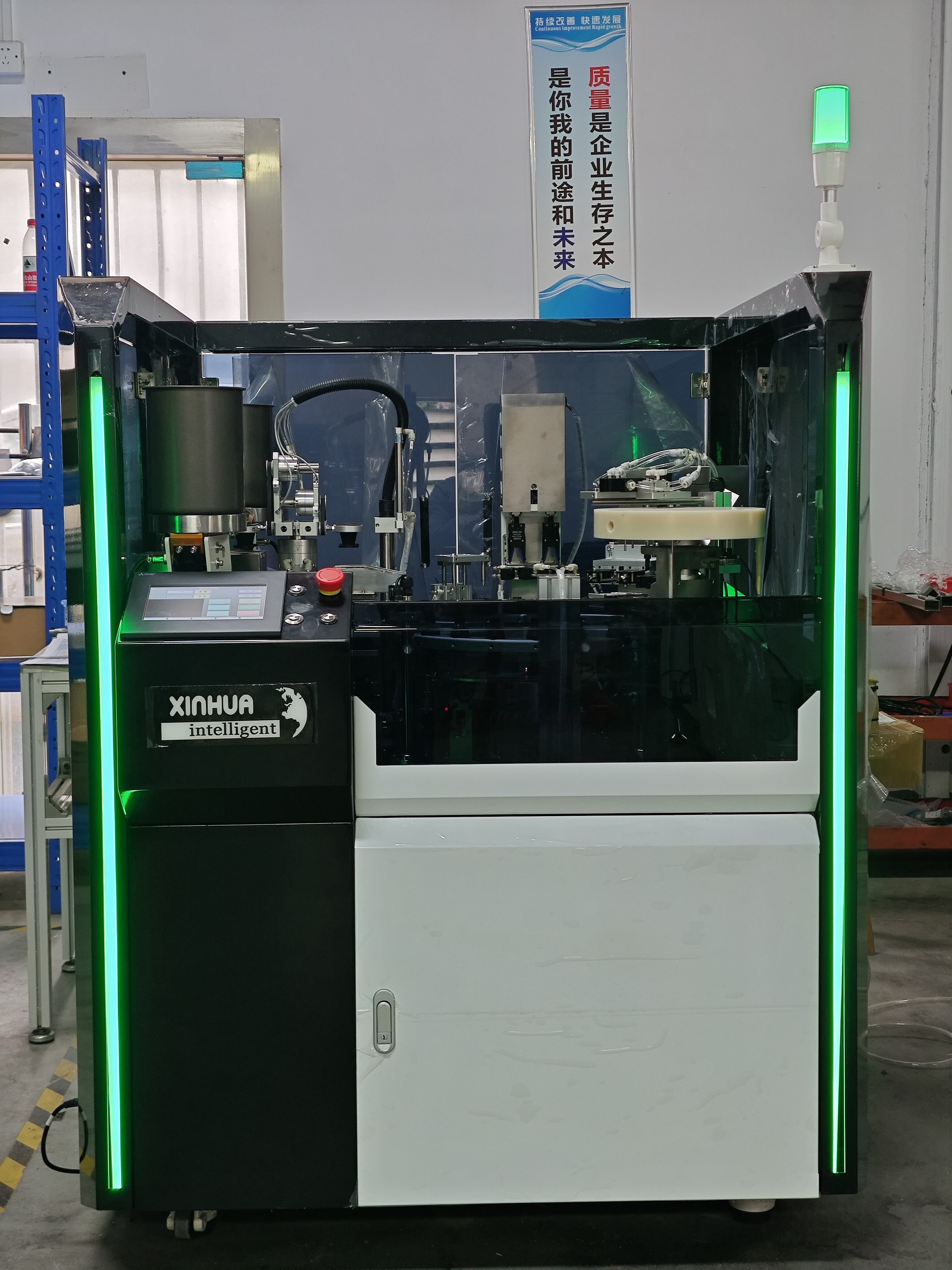

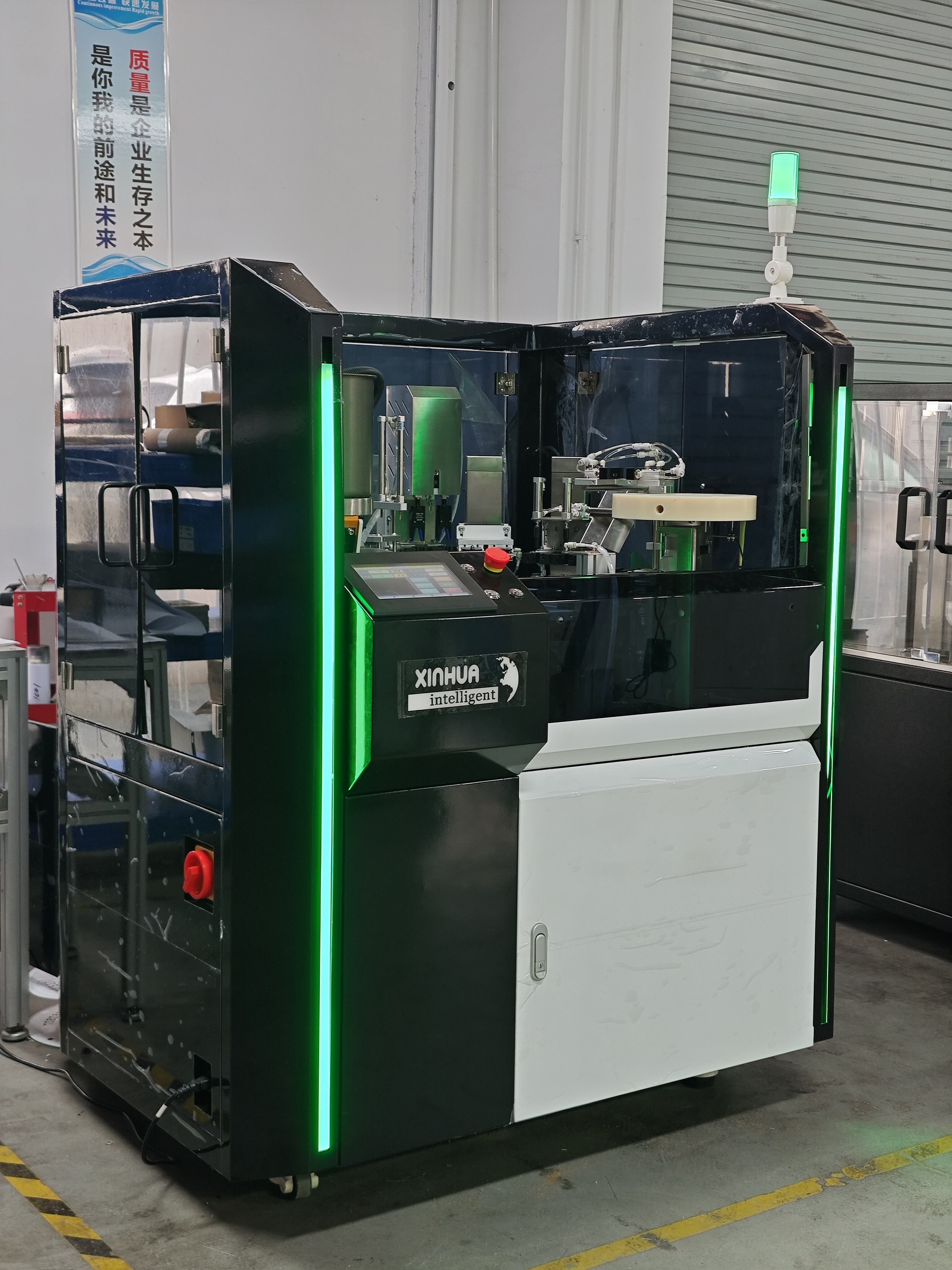

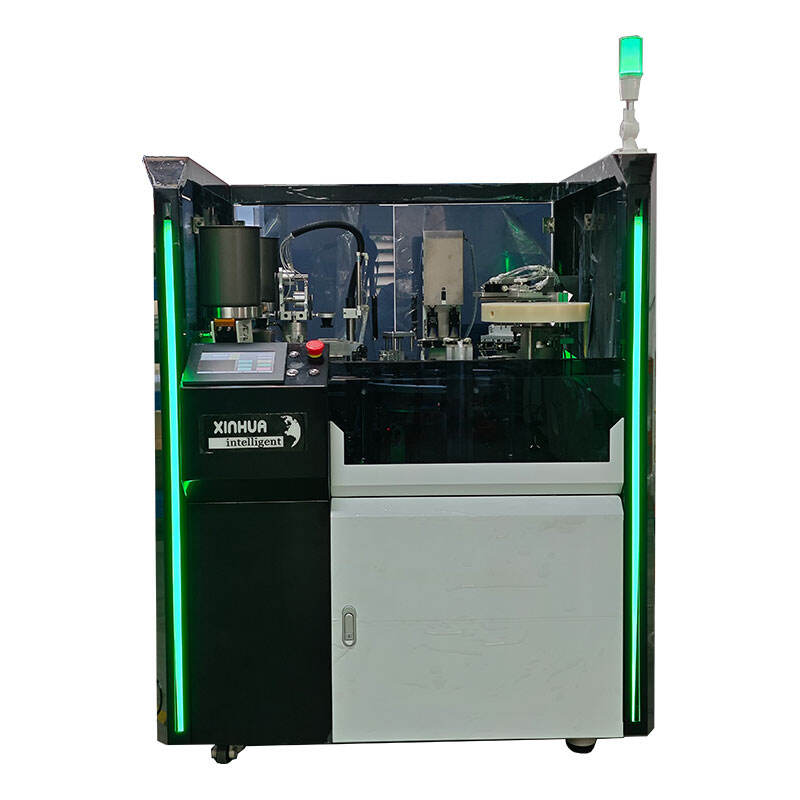

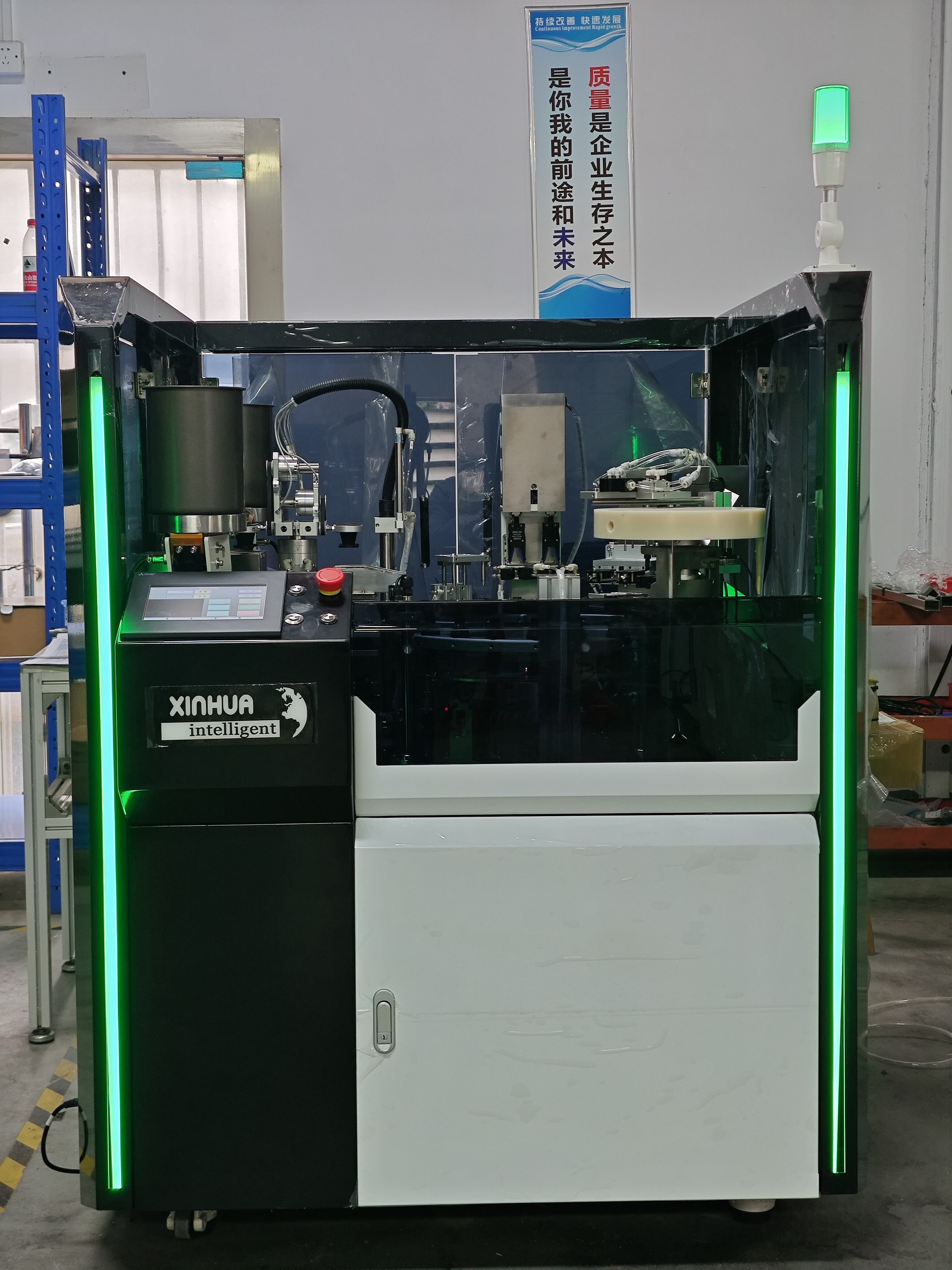

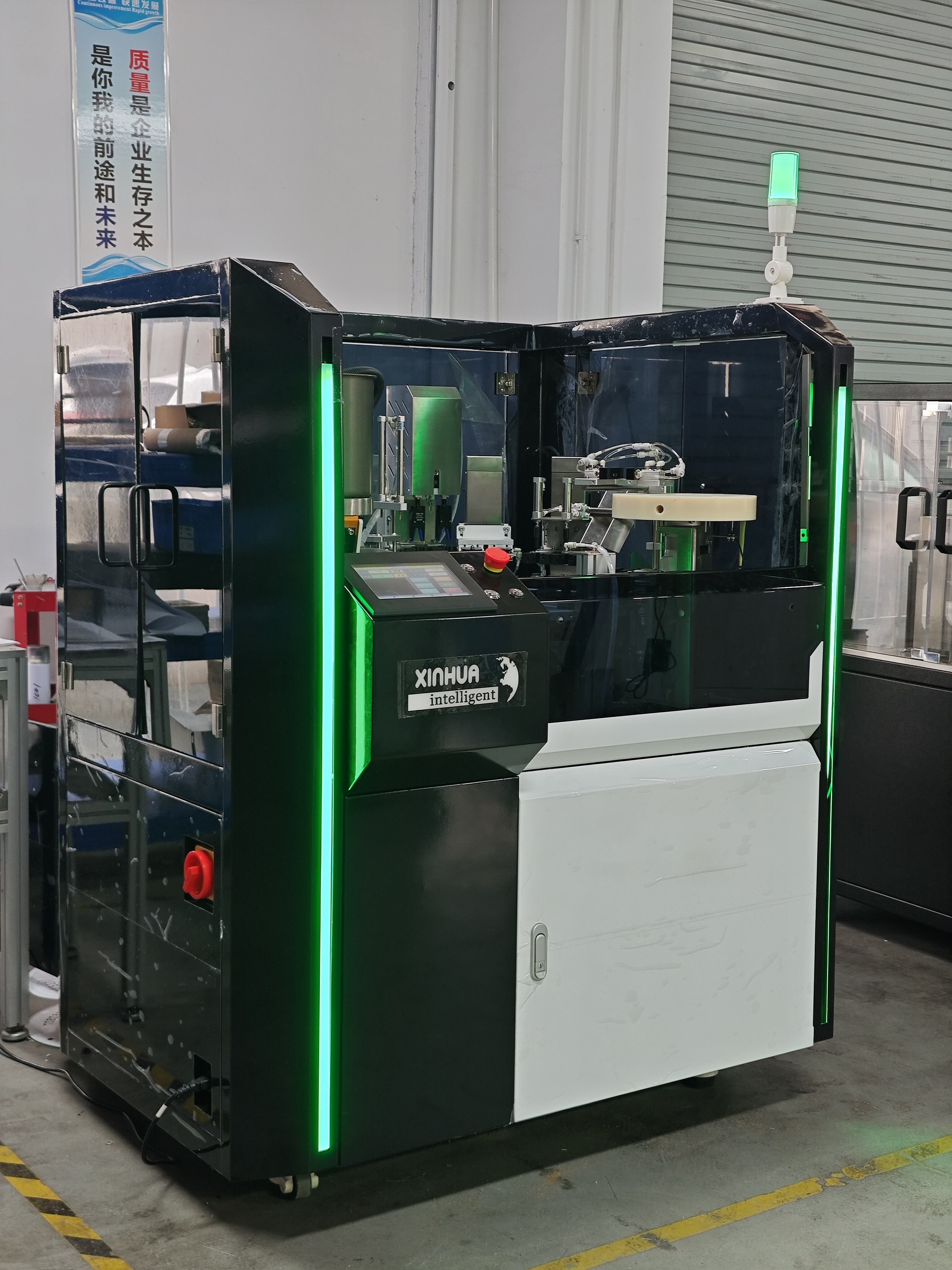

In short, automated pre-roll machines are machines that, once being set to specifications, operate automatically in the pre-roll making process with minimal human intervention. These machines still need to be monitored, maintained, cleaned, and supplied with raw materials, but they are extremely efficient at performing automated pre-roll production and even pre-roll packaging.

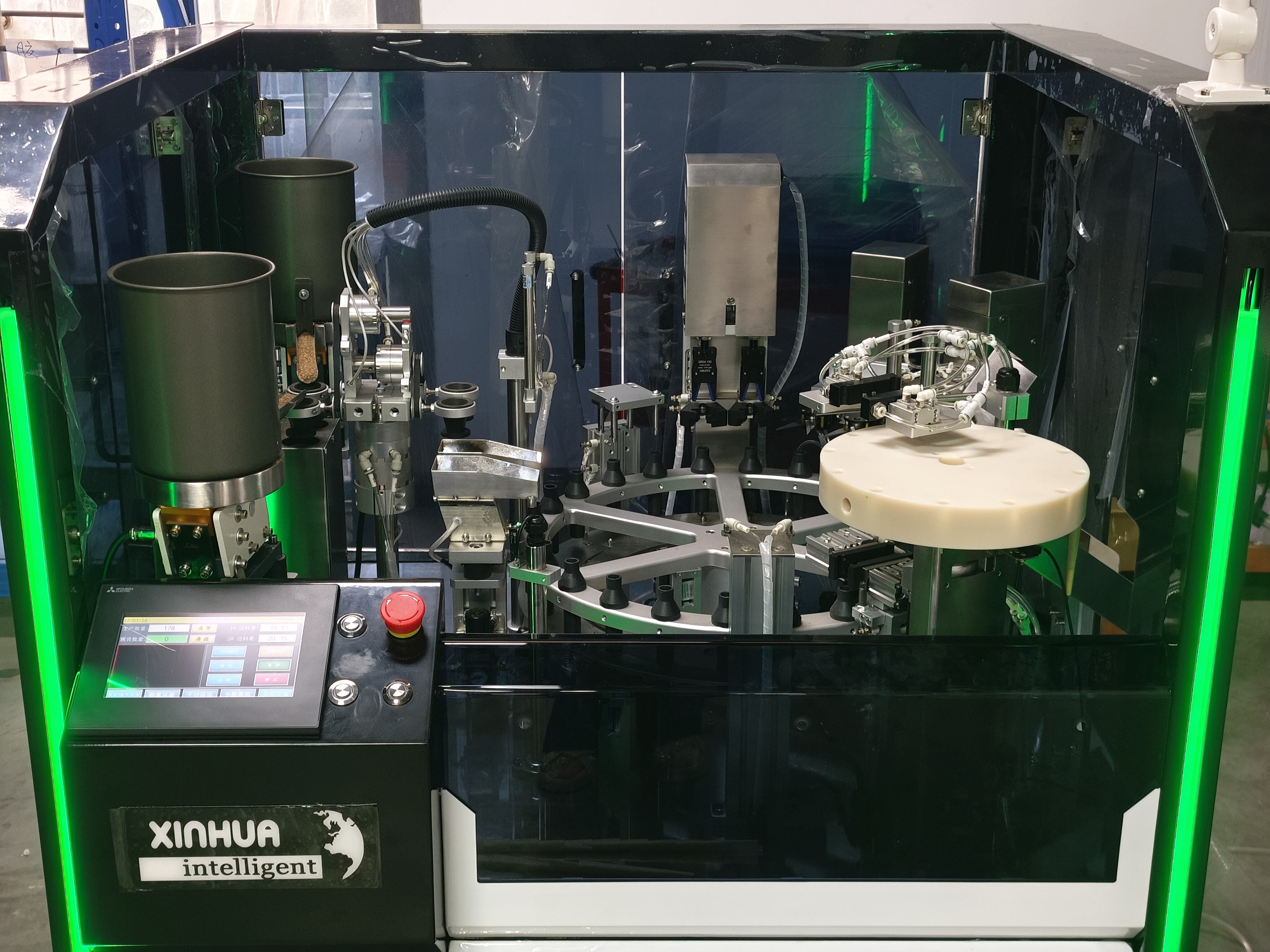

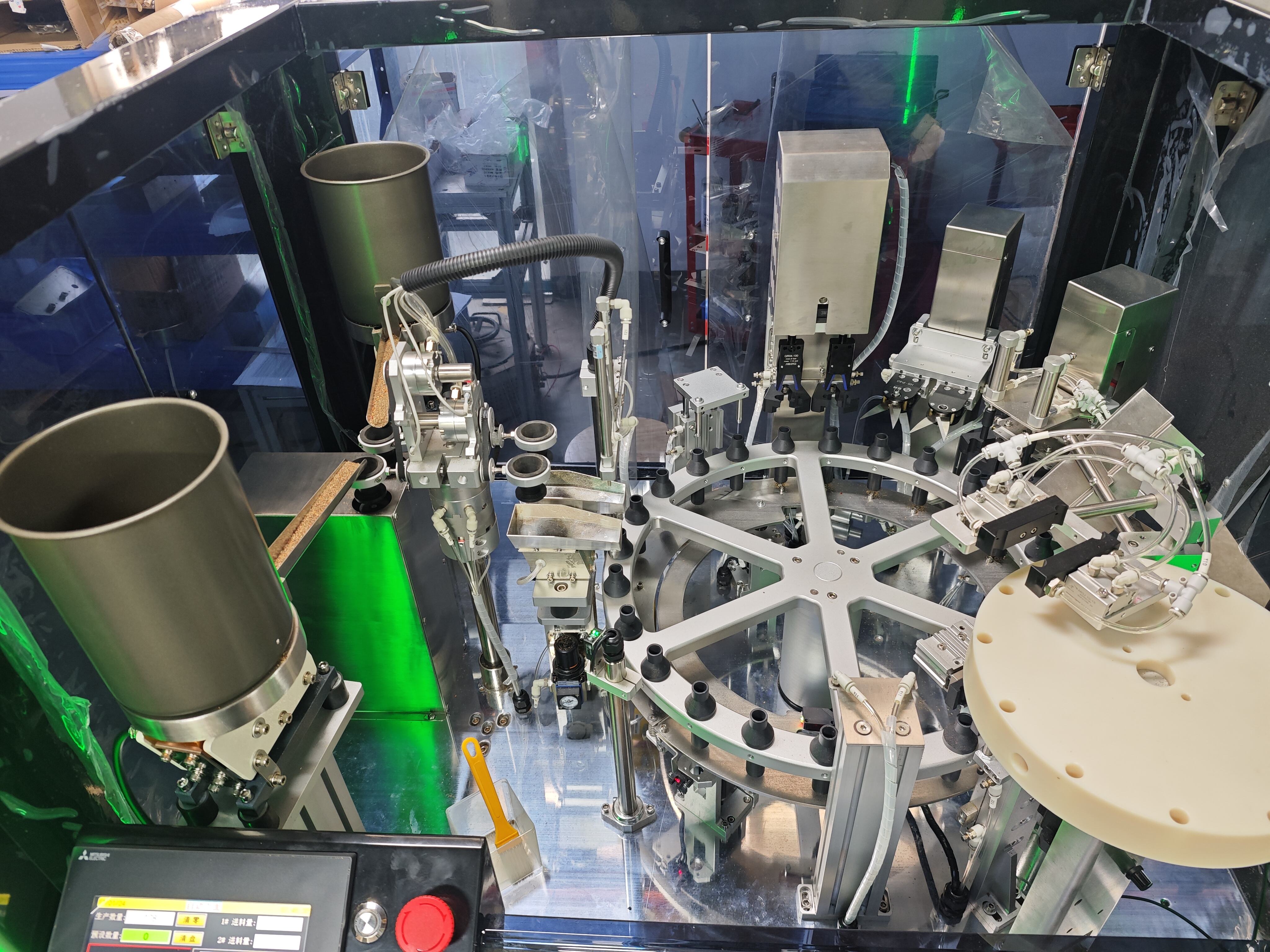

The working principle of the pre-rollers can be roughly divided into the following steps:

Dosing: The material needs to undergo an initial dosing process before it enters the forming section. This process is usually carried out by means of specific devices

Rolling: after the material is poured into the paper, the machine pinches the paper and rotates it.

Cutting: When a predetermined length is reached, the blade cuts off the excess.

Conveying: The cut finished product is fed to the next process (e. g. packaging process) or collected directly by passing it through a conveying device.

| Weight (KG) | 298 | ||

| Application | Dried grass | ||

| AutomaticGrade | Automatic | ||

| Driven Type | Electric | ||

| Place of Origin | Cuangdong,China | ||

| Waranty | 1 Year | ||

| Machinery Test Report | Not Available | ||

| Video outgoing-inspection | Provided | ||

| Core Components | Motor | ||

| After-sales Service Provided | Video technical support,Online support | ||

| Voltage | 110-240V 60hz | ||

| Brand Name | XINHUA | ||

| Dimension(L*W*H) | 111*107*144cm | ||

| Key Selling Points | Easy to Operate,Automatic,Digita | ||

| Product name | pre roll fling machine | ||

| Model | UA-1230TM | ||

| XZY kinematic accuracy | ±0.03mm | ||

| Weight | -298kg | ||

| Voitage | 110-240V60hz | ||

| Process capacity | 1600 pcs/one hour | ||

| maximum load bearing | 10kg/4kg | ||

| effective trave | 300*300*100mm |