×

×

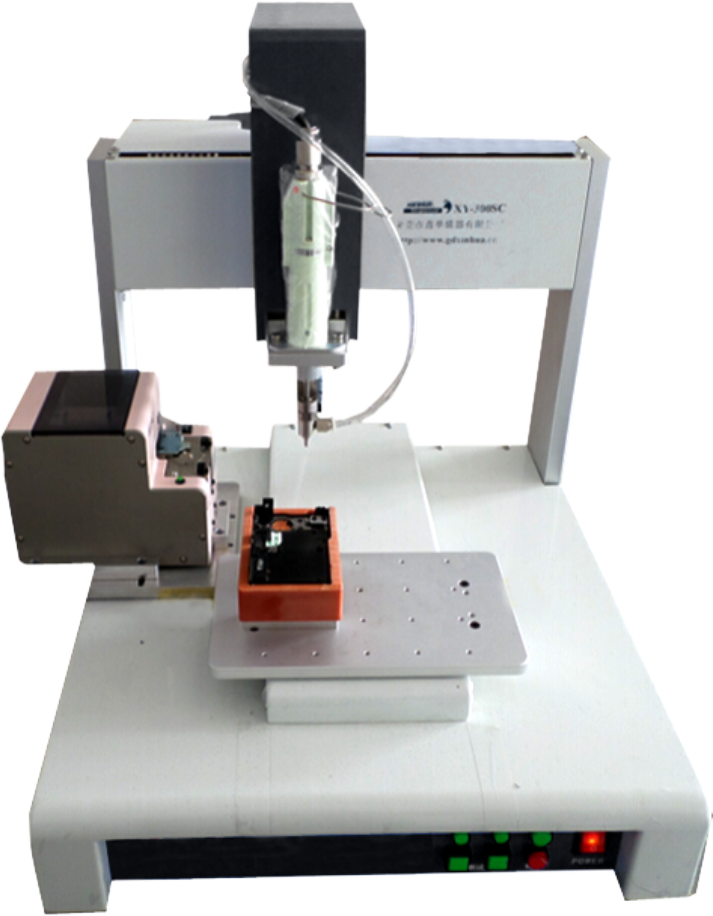

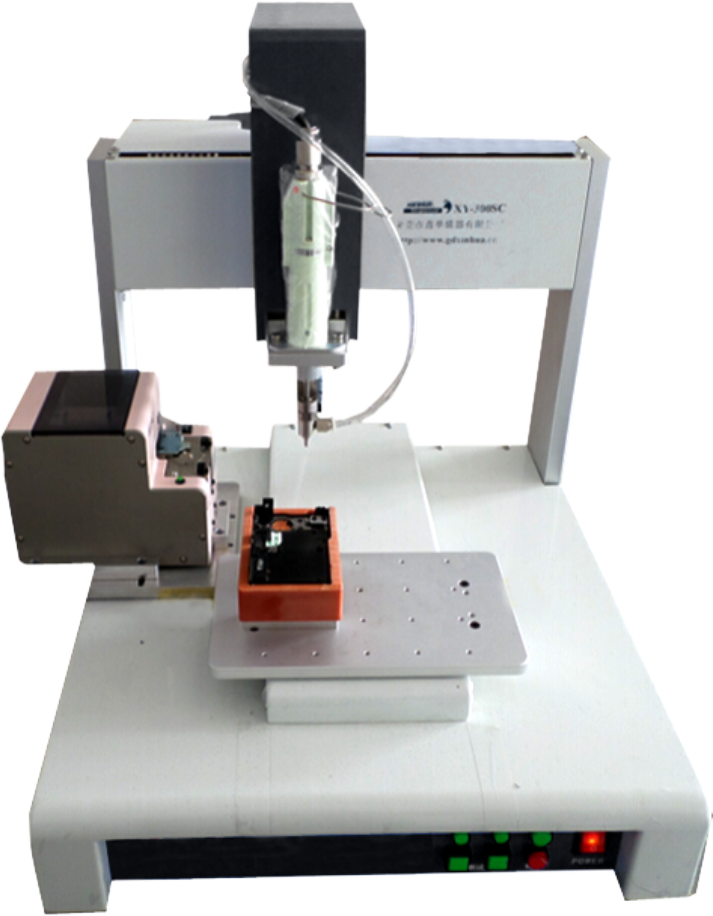

The automatic screw row unit is mainly responsible for screw screening, arrangement, material distribution, transportation and other processes. It is an important link instead of manual screw removal. Locking mechanism the locking mechanism performs the screw tightening action according to the program setting through the configured electric batch, air batch or servo motor, which completely replaces the manual operation

1. Apply to most kinds of screws.

2. Replace manual operation to carry out the specific screw-locking. Realize the mechanization production. Reduce the labor intensity of workers. It takes up a lot of work time and energy to manual placement of screws and alignment of screw heads traditionally.

3. No need to match handheld teaching device only single operation, convenient installation. Simple operation setting, workers can quickly master operation and debug.

4. Screw feeding mode: suction pay type, blowing type according to customer needs.

5. The equipment has automatic alarm function, which is convenient for maintenance and keeping machine parameters.

6. Suitable for mobile phone, digital products, photoelectric, medical, household appliances and other industries. Vacuum suction screw mode: good commonality, less error. This mode can overcome defect of the blowing screw the length to diameter ratio less than 1.2 be not fed , but also overcome stainless steel screw can not be sucked in the magnetic suction screw mode , for screw changing, just to replace the feeding component, nozzle in M1.0-M4.0 screw types. Blowing screw mode: compared with the suction type, the blowing screw is directly transported to the nozzle. Save the time to take screws back and forth in higher efficiency.

| Models | XY-300SC | XY-400SC |

| Working area X*Y*Z(mm) | 300*300*120 | 400*400*120 |

| Moving speed (mm/s) | X/Y:≤500mm/s; Z:≤200mm/s | |

| Drive mode | Stepping motor + linear guide / servo motor + ball screw (optional) | |

| Location accuracy | +001-0.03mm | |

| Control system | Moving controlling and teach pendant | |

| Screw transmission method | Suction mode /blow mode | |

| Electric screwdriver | 1pc (provide more if needed) | |

| Full-voltage | 220V50HZ | |

| Operating temperature | 5-40℃ | |

| Operating humidity | 20-90% no condensation | |

| Air pressure | 0-0.8MPa | |

| W*D*H(mm) W*D*H(mm)size | 485*545*600 | 565*605*620 |

| Weight | around 70kg | around 90kg |