×

×

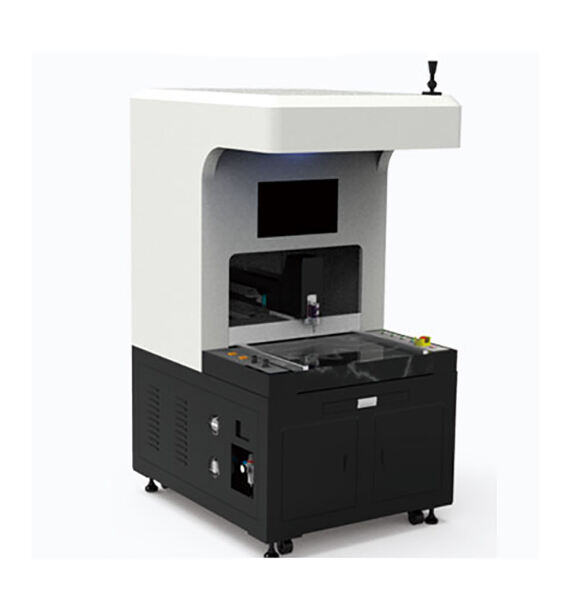

CCD vision dispensing machine the equipment uses panoramic photography automatic identification system, the equipment with great recognition ability, can quickly adapt to a variety of complex products, high stability; Adopt imported industrial lens to take photos, the pixel clarity is up to 8 million; The system has high identification accuracy and fast dispensing speed, which is widely used in many industries.

CCD system can identify products placed randomly on the fixture and can dot, draw, S, circle any graph point glue dispensing; automatically identify defective products or do not need dispensing products, at the same time equipped with long operation dispensing high efficiency, fast speed, save labor costs; the equipment can dispense in the small amount of glue carried out in the small gap in precise way to achieve the dispensing operation that cannot be completed by manual.

The equipment is divided into two station automatic and dispensing can achieve 24-hour work all day, greatly increased the production efficiency. It can choose high speed dispensing valve and injection point glue valve system, without precision fixture products put in work surface scan capture automatically generated by the visual system can automatically start point glue. It also can automatically identify non-conforming or does not need some rubber products, saving production cost.

| Models | XY-QE400 CCD-gluedispenser |

| Working area X*Y*Z*R (mm) | X400*Y400*Z120mm |

| Moving speed (mm/s) | X/Yaxis ≤500mm/s,Zaxis ≤300mm/s |

| Repeatability | ±0.015mm |

| Screen showing | Teach pendant |

| Drive mode | servo motor +ball screw |

| Fixture | some do not need fixture |

| Air pressure | 0.4~0.8Mpa |

| Full-voltage | 1.5KW AC220V 50/60HZ |

| Operating temperature | 10-40℃ |

| Operating humidity | 20-90% no condensation |

| Dimension W*D*H (mm) | W850mm*L800mm*H1700mm(reference only) |

| Weight | around 150kg |

| Daily maintenance | Regularly clean the dispensing valve and replace the sealing ring and replace needles every day/every shift |