×

×

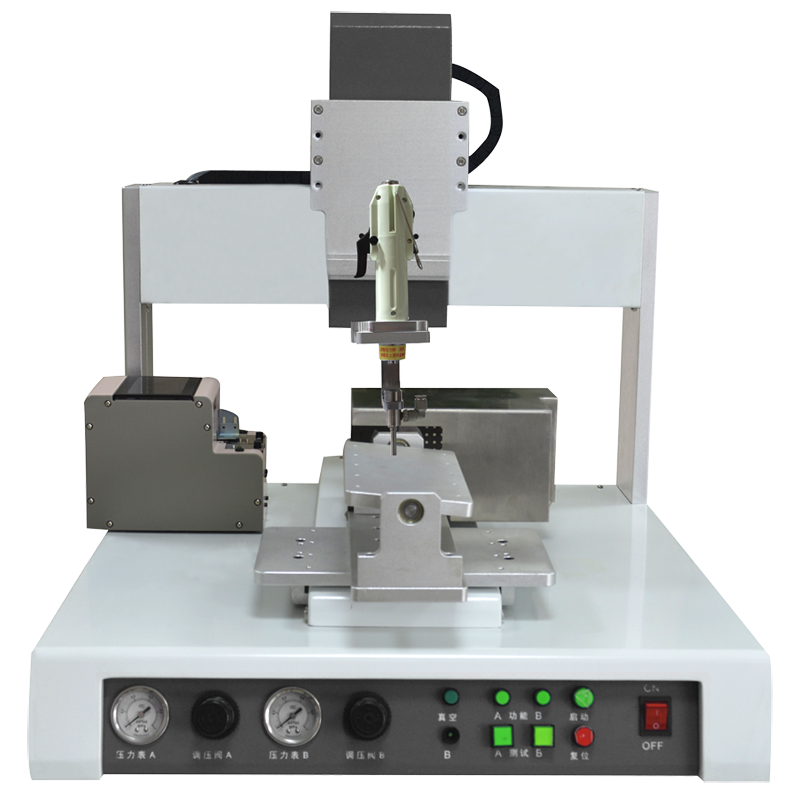

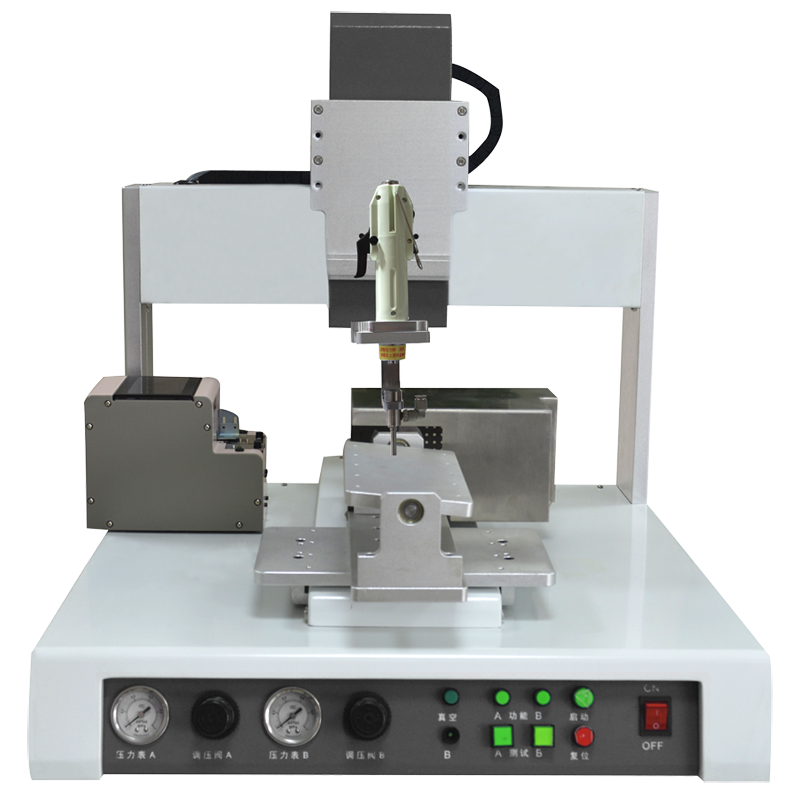

The automatic screw row unit is mainly responsible for screw screening, arrangement, material distribution, transportation and other processes. It is an important link instead of manual screw removal. Locking mechanism the locking mechanism performs the screw tightening action according to the program setting through the configured electric batch, air batch or servo motor, which completely replaces the manual operation

1. Match intelligent servo tightening device, which can monitor the screw locking torque and how depth in hole in real time, also detect whether the products are screwed in joint or not.

2. The equipment is equipped with a safety grating protection system. When the equipment is locked quickly, it also can ensure the safety of employees.

3. Product placement platform can be turned to 0~360 °, suitable for different sides of screws locking.

| Models | XY-SC400R |

| Working area | 400*300*120mm,R 0~360° |

| Moving speed(mm/s) | XY:≤500mm/s;Z:≤200mm/s |

| Drive mode | Stepping motor+straight guide/servo motor +ball screw(altermative) |

| Location accuracy | ±0.01-0.03mm |

| Control system | Moving controlling and teach pendant |

| Screw transmission method | Suction mode/blow mode (altermative) |

| Electric screwdriver | 1pc (alternative) |

| Full-voltage | 220V50HZ |

| Operating temperature | 5-40℃ |

| Operating humidity | 20-90% no condensation |

| Air pressure | 0-0.8MPa |

| DimensionW*D*H(mm) | 545*610*610 |

| Weight | around 100kg |