×

×

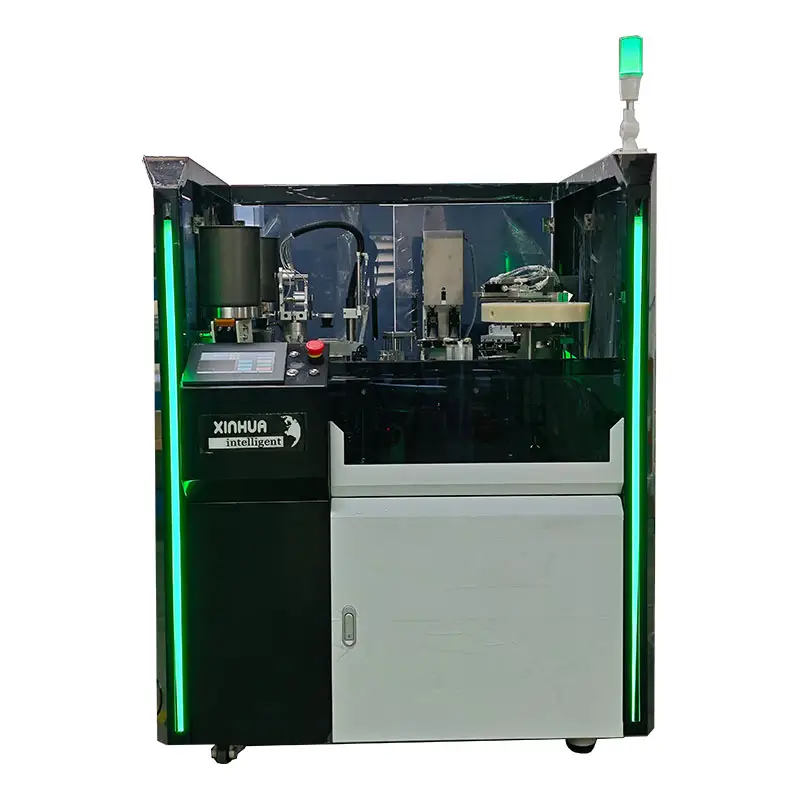

The purpose of XINHUA's Pre roll Cone Filling Machine is to facilitate the production cycle for the cannabis business with the same level of quality no matter how many fills you do. This reliable piece of equipment eliminates the tedious cone-filling process, which helps you keep up with the increasing demands. Thanks to the easy to use interface and accurate filling elements of the pre-roll Cone Filling Machine, wastages are minimal and output is maximal, thus an important equipment for your processing line.

Filling equipment can be adjusted according to various needs offered by our machine with its adjustable settings: the fill volume and the filling speed. This versatility enables quick set-up for the production of other product lines, standard or specialty pre-rolls. And the practical structure of Xinhua Pre Roll Cone Filling Machine offers a high level of performance, giving you many years of help.

In the fast world of production, the term efficiency is of utmost importance. The XINHUA Pre roll Cone Filling Machine is designed in a way such that it improves the efficiency of the production line by introducing preciseness into the filling action. The machine in this case requires a lot of cones, which means that it helps businesses expand their operations without lowering the standards. It is constructed in small dimensions allowing it to be incorporated into any production system making it suitable for all levels of manufacturers. Due to the Xinhua’s pre roll Cone Filling Machine, companies are able to reduce labor costs, boost the output, and streamline day-to-day operations.

The purpose of the XINHUA Pre roll Cone Filling Machine is to increase the speed and accuracy of filling pre-rolled cones. This machine, suitable for any cannabis producer and dispensary ensures uniformity in filling and less time and labor in the manual processes. The filling machine is easy to operate as the operators will only need to vary the different settings basing on the types of cones and filling materials used. This adaptability not only improves productivity but also facilitates high precision filling appropriate in meeting increasing consumer demands. It is thus incidental that filling machine Xinhua pre roll cone incorporates an enhancement in quantity puts the quality of output that is provided for within the expectations of the clients.

XINHUA appreciates the fact that different businesses are involved in the business for divergent reasons and this has led our Pre roll Cone Filling Machine for wig to have different production settings that can be adjusted. For instance, if you are using different cone sizes and design materials or fill them to different weights, this machine is easily able to with your requirements. The design of the control panel is user-friendly in that one can easily change parameters, making it ideal for manufacturers who have a wide array of products. This type of versatility not only optimizes the manufacturing process with the reduced lead time but also enables businesses to be adaptable to the changing needs of the market and its customers.

This high-end XINHUA Pre roll Cone Filling Machine was assisted in construction with quality control measures to make sure that every cone meets certain best practices in the industry. Quality matters and that is why when it comes to any product sold, there shall be no argument on its quality assurance. Through its sophisticated fill monitoring systems, the machine will monitor the fill weights and notify the relevant personnel in cases of any discrepancies and appropriate measures taken. This is necessary as it helps avoid expensive odious mistakes and unpleasant reworks in the end making it efficient regarding economy, time and resources. With the growth in quality of these xinhua pre roll Cone Filling Machine, it is also evident that the business market reputation of these businesses will also rise to a higher level and that is to excellence and reliability.

Dongguan XINHUA Intelligent Manufacturing Co., Ltd., since its establishment in 2010, has been deeply engaged in the R&D and production of intelligent equipment. We focus on providing high-quality dispensing machines, automatic dispensing machines, dual-liquid dispensing machines, vacuum dispensing machines, automatic screw locking machines, and visual dispensing machines for global industries such as new energy, semiconductors, power supplies, batteries, communications, electronic components, home appliances, 3C digital, automobiles, and lighting.

Our products have established a good reputation in the industry with advanced technology and outstanding performance. Our R&D team continuously innovates, introducing automation control technology and visual recognition technology to ensure the efficiency, precision, and stability of the equipment. Our equipment can be customized according to customer needs, meeting the production requirements of different industries and products.

In addition to the excellent performance of the products themselves, we also focus on providing comprehensive services to customers. We have a professional customer service team and technical support team to provide pre-sale consultation, mid-sale training, and after-sale service, ensuring that customers can fully utilize our equipment to achieve production goals.

Tailored automation equipment to meet specific industry needs.

eliable machinery built for long-lasting performance and precision.

Dedicated technical assistance ensures smooth operation and maintenance.

Efficient shipping with timely and professional support.

A pre roll cone filling machine is a device designed to automate the process of filling pre-rolled cones with various substances, typically used in the cannabis industry. It streamlines the filling process, ensuring consistent quality and efficiency.

The machine operates by utilizing a hopper to hold the material and a mechanical or pneumatic mechanism to fill the cones. Operators place empty cones in the machine, and the filling process is initiated, allowing for a quick and uniform fill.

The pre roll cone filling machine is versatile and can be used with various materials, including ground herbs, tobacco, and other dry blends. However, it is essential to ensure the material's consistency for optimal performance.

Regular maintenance includes cleaning the machine after use, checking for any clogs or wear on parts, and ensuring all mechanisms are functioning correctly. It is advisable to refer to the manufacturer's guidelines for specific maintenance procedures.

many pre roll cone filling machines are designed to accommodate various cone sizes. Some models come with adjustable settings or interchangeable components to fill different cone sizes, enhancing their usability across different production needs.